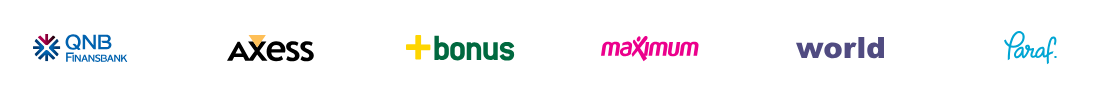

Turning

The ISO turning range with innovative cutting grades and modern geometries turns our customers’ cost spiral downward. Boehlerit offers the optimum indexable inserts for every turning application, e.g. for steel, cast and aluminium machining and the cutting of super alloys with difficult chip formation.

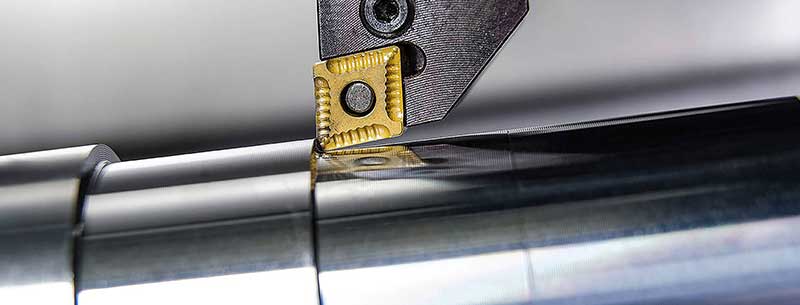

Milling

The quality standards in milling have been defined by the Boehlerit cutting experts for decades now. The development engineers in the Austrian steel industry town of Kapfenberg put all their technical know-how into a dynamic FEM design (finite-element method) for Boehlerit milling equipment to create stable milling tools.

Drilling

Specifically adapted to the ever-increasing machining requirements, Boehlerit offers a broadly diversified product portfolio in the drilling sector which, thanks to the optimal design of cutting materials and geometries made from various materials, are used in general mechanical engineering.

Threading

The Austrian carbide and tool specialist Boehlerit continues to move towards becoming a full-range supplier and develops balanced geometries, with the aim of delivering top performance over a very wide range of materials and applications. This results in efficient and highly productive tool solutions.