Crank shaft machining

The right tool for every processing step Boehlerit has long-standing expertise and a full range of tools for crankshaft and camshaft machining at its disposal. The tools are designed on a case-bycase basis, in accordance with individual customer requirements.

Bar peeling

Bar peeling refers to a kinematically reversed longitudinal cylindrical turning process and is one of the most sophisticated machining processes around. The workpiece is concentrically fed through a rotating shaving head and the process know-how is mostly concentrated directly at the working area. Boehlerit provides complete tooling systems for successful rotary shaving, consisting of a bar peeling head, holder and cartridge.

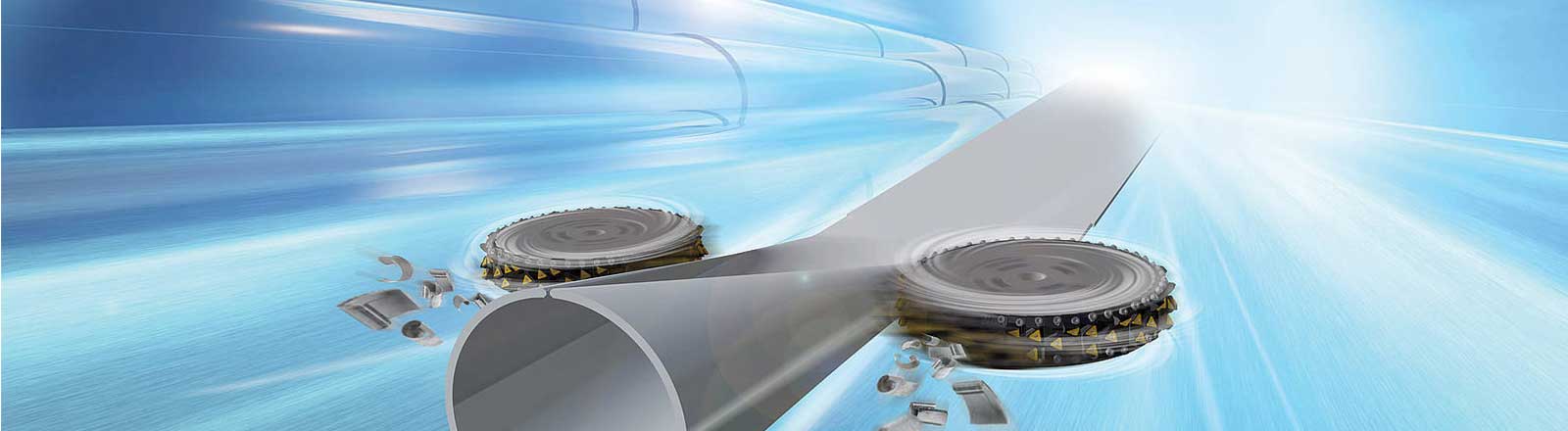

Tube processing

Boehlerit offers an unrivalled diversity of products and the full range of cutting and machining solutions for the production of large-diameter pipes. In addition to various components for pipe-end machining, the standard processes of plate edge machining are also used in other lines of industry.

Rail- and turnout machining

Perfectly maintained rails are a prerequisite for excellent riding comfort, a long tool life and a high level of operational safety. With our specially designed track-milling system, worn rails are given a new lease of life, with great precision and efficiency.

Milling

The new modular tool system from Boehlerit for general heavy-duty machining covers diameter ranges from 160 to 400 millimetres. It can be equipped for the face milling of a very wide range of materials, such as steel and stainless steel to aluminium to titanium, by simple exchanging of the cartridges and indexable inserts.

Turning

Decades of experience gained in the steel industry, plus innovative geometries and cutting grades have added up to develop a comprehensive range of cutting solutions in the field of heavy-duty cutting, slab milling, wheel set machining and roll turning.

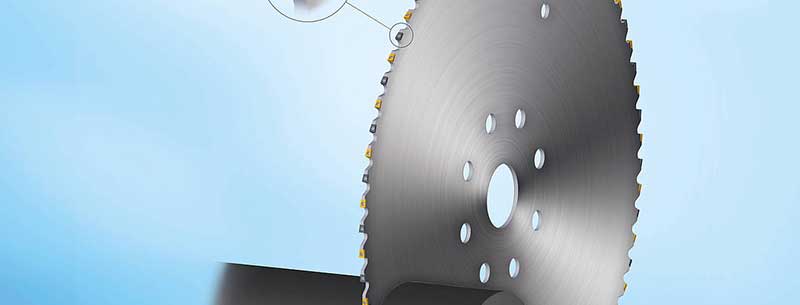

Sawtec 2.0

Boehlerit is a true pioneer in the development of cutting materials from carbide and a European premium manufacturer whose outstanding expertise results from its close links with the steel industry. The result: high-end grade solutions for rotating carbide tools that are suitable for a wide range of applications.

Specialist in heavy duty turning

Decades of experience gained in the steel industry, plus innovative geometries and cutting grades have added up to develop a comprehensive range of cutting solutions in the field of heavy-duty cutting, slab milling, wheel set machining and roll turning.